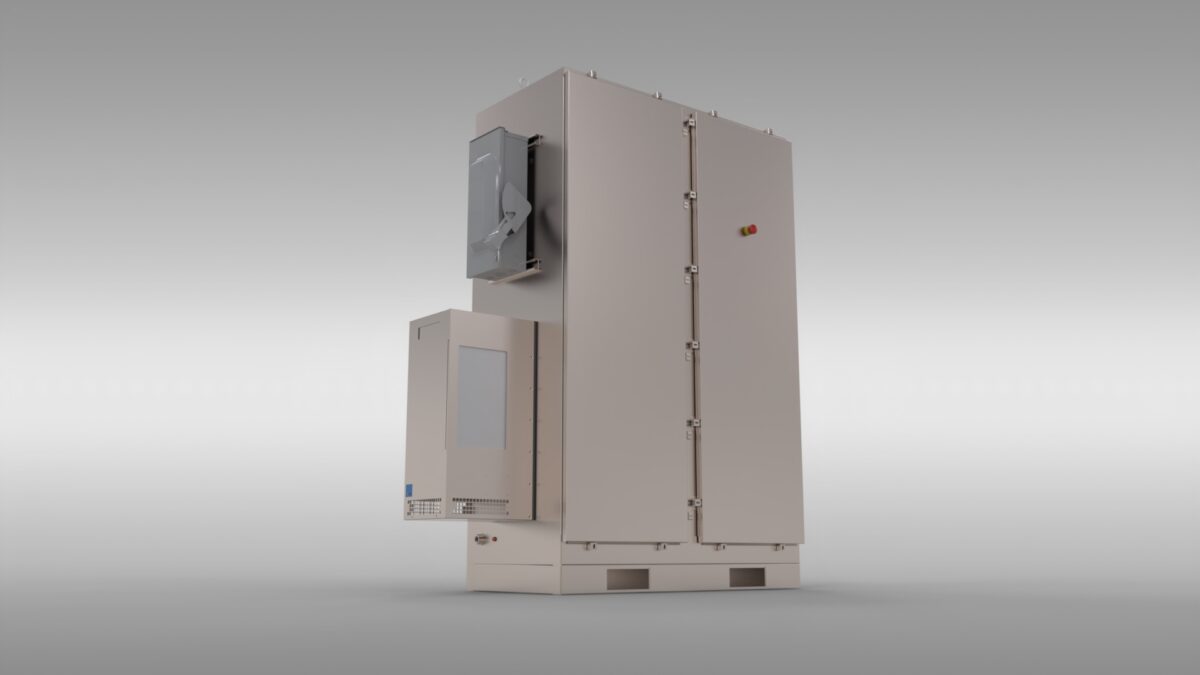

IMPACCT MPD Control System

The Stasis IMPACCT™ MPD control system enables precise and automated control of the managed pressure drilling process, resulting in enhanced operational efficiency. The IMPACCT™ control system features a compact design and the processing power to automatically control multiple chokes to maintain constant bottom hole pressure, making it ideal for integration into rig systems or for use as a stand-alone service.

-

PLC Controller – monitors inputs simultaneously, adjusts choke to maintain optimal annular pressure, and maintains bottom hole pressure during MPD

-

HMI – monitors key drilling parameters in any condition and enables crew interaction with the driller during connections

-

Multiple Control Modes –

-

Position Control – Allows for choke position to be controlled directly by user

-

Setpoint Control – Automated control of surface back pressure by entering desired target pressure to be applied.

-

Automated Ramp Control – Automated control of surface back pressure by utilizing desired target pressure in correlation with current flow rate.

-

Trip Control – Automated control of surface back pressure during tripping events by entering desired target pressure during surge and swab operations.

-

-

Integrated Data Logger – Capture critical data for analysis, with ample storage capacity for long-term campaigns

Ruggedized Housing Design

-

316 stainless steel enclosure

-

Built-in redundant uninterruptible power supply – system will operate without electrical power

Made in the USA