TITAN 5 ARES 3078 – DUSA

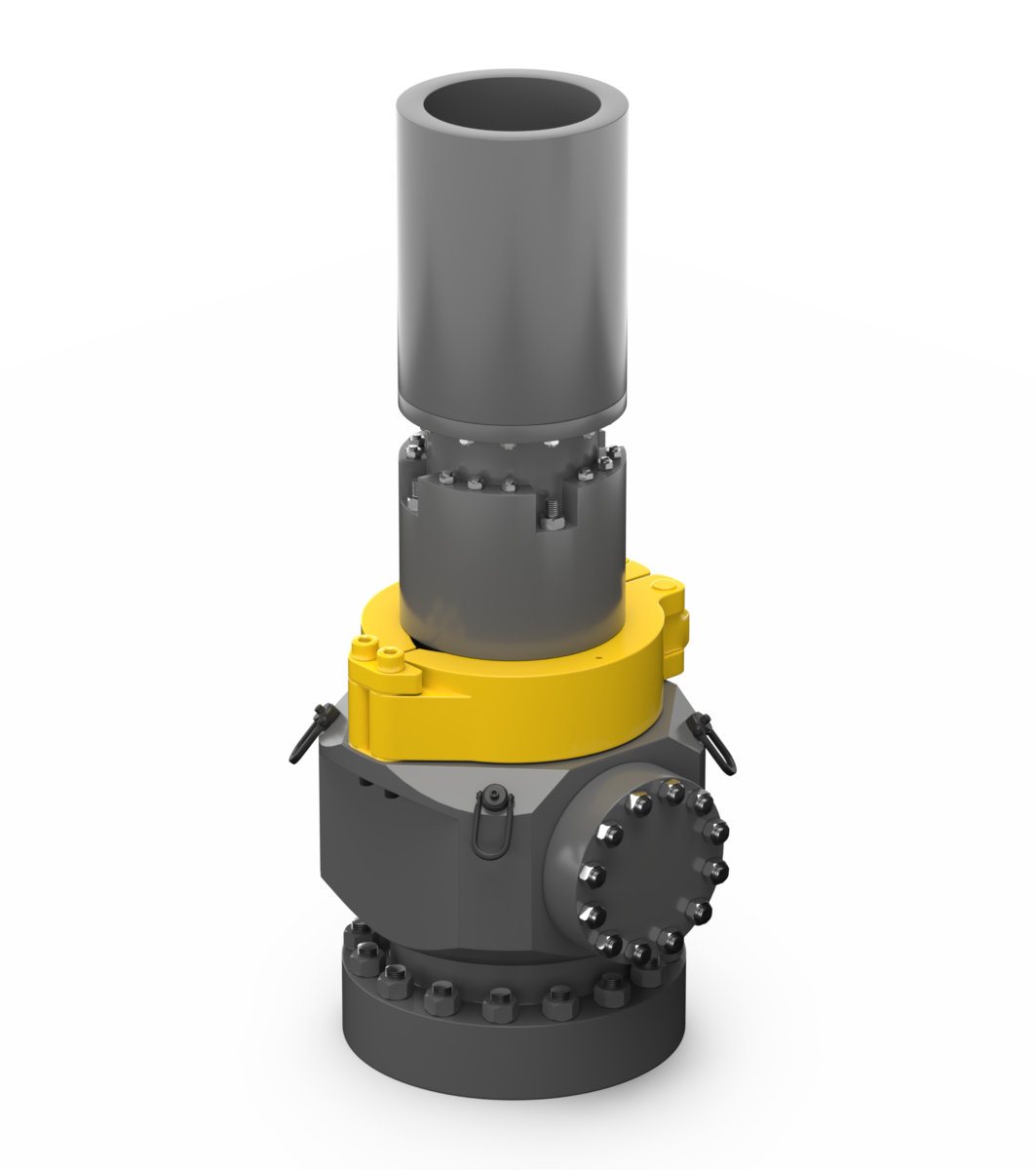

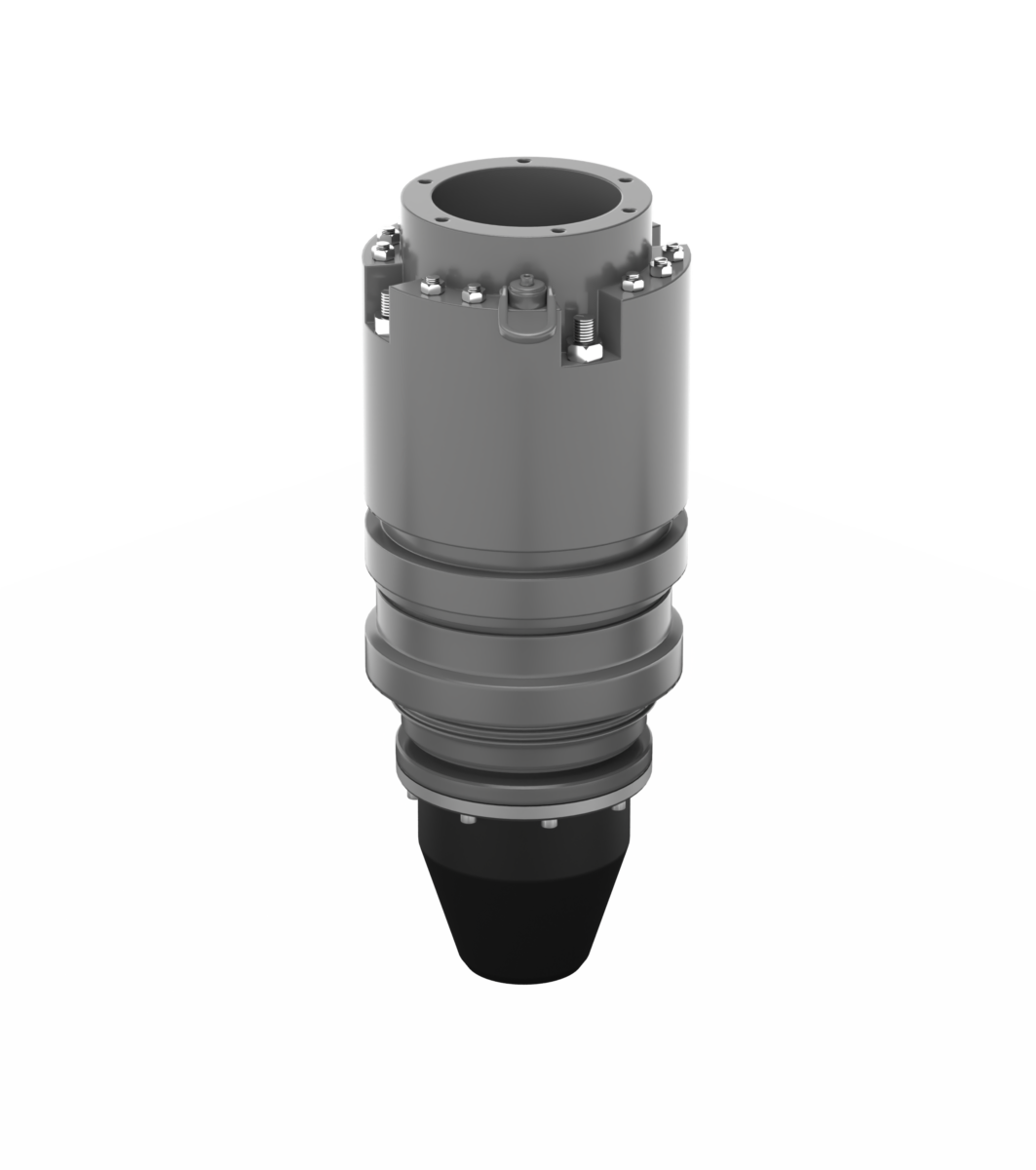

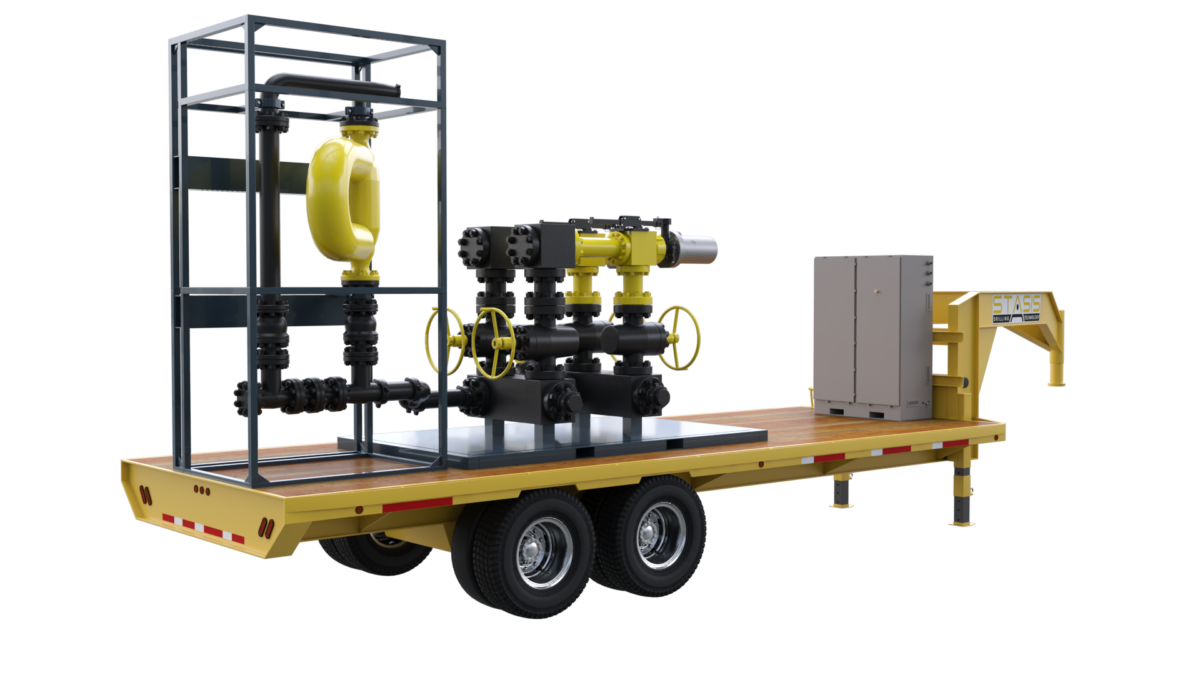

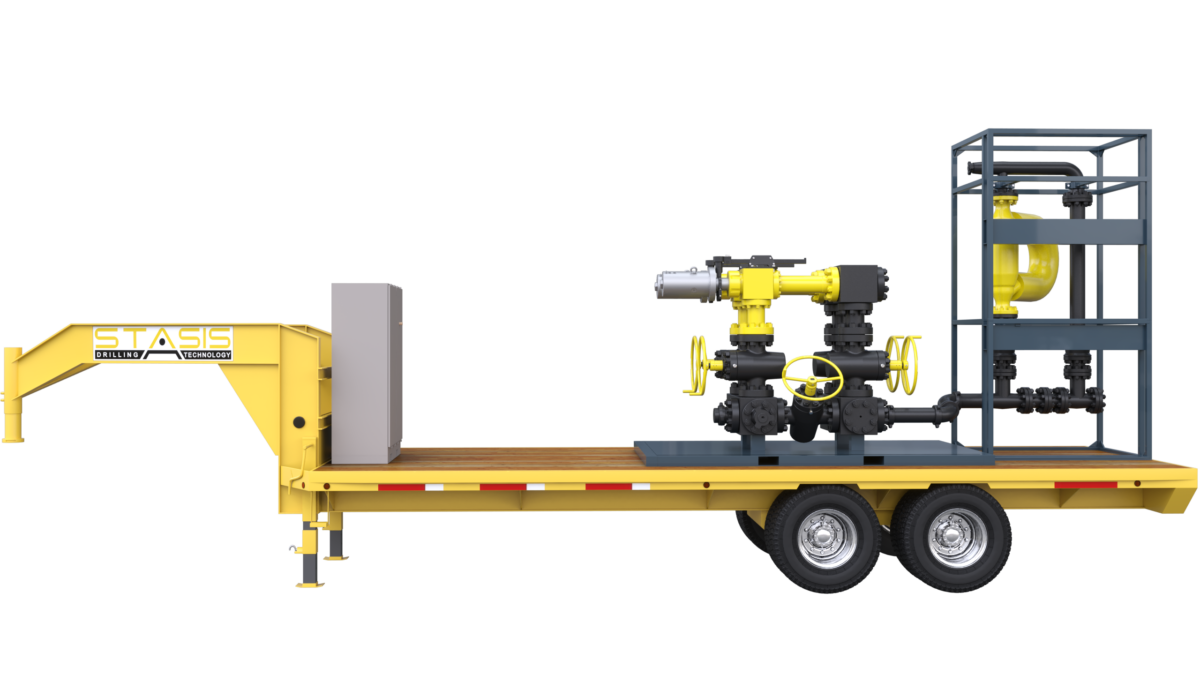

The TITAN 5 Rotating Control Device (RCD) provides reliable sealing performance for your drilling and tripping operations. The RCD coupled with the ARES 3078 bearing assembly delivers a dual sealing element capable of performing up dynamically up to 200 RPM @ 1,000 psi. The RCD body provides dedicated dual outlets for both conventional drilling (7-1/16″ outlet flange) and Managed Pressure Drilling (MPD) (4-1/16″ outlet flange) operations to simplify the installation process and to allow for an easy transition of any operation to MPD without costly downtime and fabrication. The RCD body also provides a lower 13-5/8″ 5K swivel flange to assist in optimizing alignment of outlet flanges and improve installation time and handling.